Our New Factory

-

Sustainable Factory Design: Built for a Greener Future

At Solar Waves, sustainability starts at the source. Our innovative factory designs are crafted for environmental responsibility, utilizing green aluminum extrusions to reduce carbon footprints from the ground up. Fully relocatable, these factories can be seamlessly moved to new locations as your needs evolve, ensuring flexibility and minimizing environmental impact.

Harnessing the power of solar, each factory is equipped with rooftop solar panels, generating clean energy to power operations. Designed with a lean manufacturing pipeline, our process maximizes efficiency—from receiving parts from trusted aluminum and photovoltaic manufacturers to precise assembly and streamlined packaging into shipping containers, ready for delivery.

Experience a factory design that’s as forward-thinking as the products it creates. With Solar Waves, you’re choosing a sustainable, adaptable, and efficient approach to solar manufacturing that meets the demands of today and the challenges of tomorrow.

-

IntermediateInspired by Automotive Innovation: Redefining Solar Manufacturing

At Solar Waves, we take inspiration from the precision and efficiency of the automotive industry's assembly lines, applying their proven principles to solar manufacturing. Our factories are designed with automation at their core, integrating advanced robotics and pneumatic systems to drive unparalleled efficiency and consistency.

By harnessing cutting-edge technologies, we streamline the entire assembly process—moving solar arrays seamlessly through each stage of production and ensuring precise, automated assembly. This results in faster production times, reduced costs, and consistently high-quality products that set a new standard in the solar industry.

Discover how Solar Waves is revolutionizing solar manufacturing with the best practices from the automotive world, delivering superior solar solutions with the speed and precision of a finely-tuned assembly line.

-

Packed and Ready for Shipping: Efficiency at Every Step

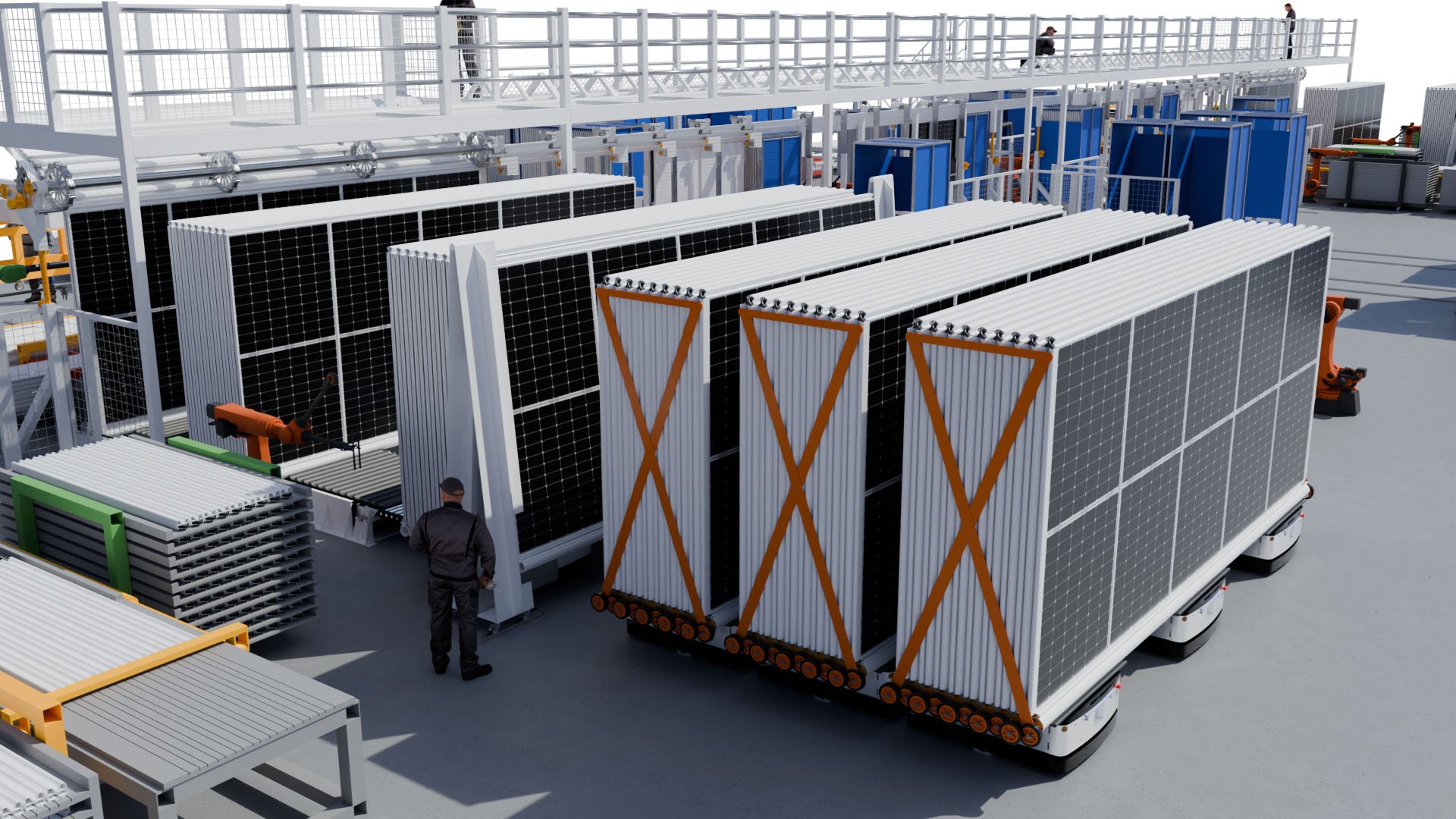

At Solar Waves, our factory design is built for speed, precision, and cost efficiency. With fully automated assembly lines, components are fed into different stations where they are meticulously assembled into complete solar arrays, all without manual intervention.

Our goal is simple: to have solar packs fully assembled, packed, and ready for shipping in record time. This streamlined process not only slashes production costs but also accelerates delivery, ensuring your solar solutions arrive swiftly and can be deployed effortlessly on-site.

From factory floor to installation, Solar Waves delivers a seamless experience, making your transition to renewable energy faster and more efficient than ever. Choose us for a smarter, faster, and more cost-effective solar solution.

Fully Automated Production for High-Performance Solar Arrays

At Solar Waves, our assembly line is meticulously designed for peak efficiency and simplicity. Components are delivered on specialized carts, optimizing the flow and speed of production. With automation at the heart of our process, solar arrays are assembled seamlessly, requiring minimal manual intervention—only the wiring is done at dedicated stations alongside the line.

Once the arrays are fully assembled, our patented airfoil, complete with pre-wiring and plumbing, is swiftly attached to the finished packs. From there, it's a straightforward process: packs are loaded into shipping containers, ready for rapid deployment to your site.

Experience the power of lean manufacturing with Solar Waves, where cutting-edge automation meets precision engineering to deliver solar solutions that are quick to assemble, easy to transport, and ready to perform. Choose efficiency, choose Solar Waves.